GROWING HEMP FOR FIBER

Types of Hemp Fiber

Hemp stalks contain two main types of fiber: bast or long fibers found in the bark (skin) and hurd (shive) or short fibers located in the core of the stem. (Figure Right)

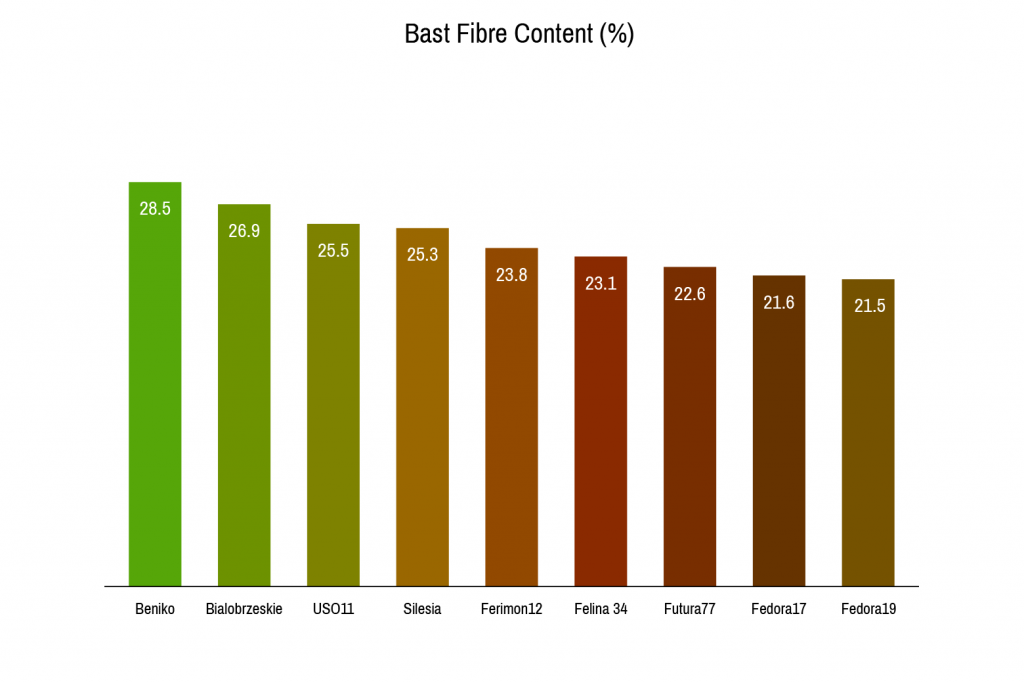

Depending on variety (or usage type) and planting density, bast fibers typically account for 20-30 % of the stalk.

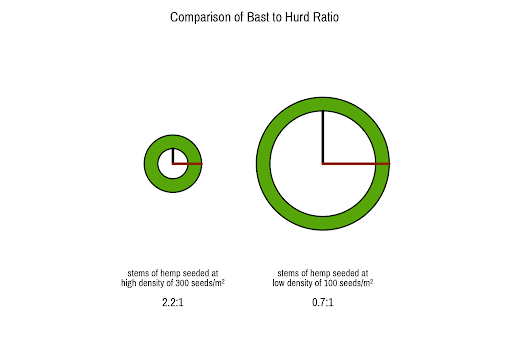

Fiber type varieties seeded at a low rate (i.e. 20 kg/ha) frequently generate tall, extensively branching plants (Figure iv) with thick stems, often exceeding one inch in diameter at the base (Figure v). Such plants are characterized by low ratio of bast to hurd fiber (Figure vi) and low quality of bast fiber (high proportion of short bast), both in the mainstem and in the multiple secondary branches.

Monoecious Hemp Head

An ideal monoecious plant will have a few male flowers arranged in whorls at the base of the flower head, while the female flowers are formed at the top. After shedding pollen, the male “flower” dries up and disappears. Monoecious plants are 30% to 40% self-pollinated.

Fiber type cv. Silesia seeded at rate 33 lbs/acre

There are two types of bast fibers:

- Primary bast fibers – make up 70-90% of the bast. They are characterized by long length (up to 50 mm), high cellulose (50-70%) and low lignin (about 7%) content. These fibers are the most valuable part of the stalk.

- Secondary bast fibers – comprise the remaining 10-30% of the bast fibers. They are shorter (approximately 2 mm), more lignified and hence of lower value for some applications (i.e. textile). Low stand density of hemp crop favours development of this type of bast fiber.

Hurd is the short fiber (about 0.5 mm) found in the inner woody core of hemp stalks. Hurd accounts for 70-80% of the stalk and typically contains 20-30% lignin. For millennia, hemp was grown for bast fiber, primarily for textile applications, while hurd was considered a waste by-product of bast production.

In addition to genotypic differences, bast fiber content in the stems can be modified by seeding density. Higher bast fiber content is found in heavy seeded fields (40-60 kg/ha) that form a dense canopy of slender, unbranched plants (Figure iii), producing high yields of superior quality bast fiber.

Stems of cv. Silesia seeded at 110 lbs/acre (left) and 33 lbs/acre (right)

Owed to their different physical properties and chemical composition, bast and hurd fibers are suitable for a wide range of industrial applications including bio-composites, construction materials, textiles, insulation, bedding, paper production, ropes and twines and many others.

Until recently, major breeding efforts of the fiber usage type varieties were focused on increasing bast fiber content of the stem, mainly for textile industries. Revival of hemp production during the last decade resulted in developing applications for hurd as well, with building products being one of the chief materials driving hemp for fiber expansion. Biofeedstock needs for eco-friendly composites and plastics will further increase hemp fiber demand.